My Fitech Easy Street Has No Rpm Reading

The engineers at FiTech have made an art of building EFI systems that are designed to upgrade carbureted daily-drivers and race vehicles. They've enabled going to fuel injection with the least obtrusive modifications from the car's original configuration. They offer everything to successfully swap over to digital fuel squirting, and even offer products designed to simplify the install.

Considering Your Configuration

While the process has gotten progressively easier to install fuel injection, we were still hearing some questions as to what significant considerations reside under the throttle body that folks need to consider. As EFI has become such a game-changer, and swapping over has become a one part-number process, we wondered if there might be something between the valve covers that might create a snafu for those seeking to make the jump.

Even with all the improvements that EFI can bring to fuel control, an engine is still basically an air pump. As such, using a single or dual-plane intake will have the same effect on EFI as it would on a carbureted engine.

We spent some time with FiTech owner, Ken Farrell, and asked him a few questions an enthusiast might have when making the swap or building an engine designed to utilize this modern technology.

Are there any differences between single- and dual-plane intakes when using fuel injection? Do the same rules apply as with the carb?

When using a throttle body fuel-injection system, you are introducing fuel at the same location as a carburetor. This allows both single- and dual-plane intakes to be used with the same characteristics that they have with a carburetor.

FiTech EFI uses an annular discharge to provide fuel, but unlike a carb, it is driven by higher pressure in the fuel line, not by the lower pressure in the intake.

Does removing the vacuum dependency of a carb to deliver fuel have specific benefits?

Electronic fuel injection uses pressure to introduce fuel into the engine. This gives the ability of immediate fuel delivery on tip-in of the throttle. This allows for better throttle response over a carburetor.

How does camshaft duration and centerline affect fuel management with EFI?

FiTech EFI systems use a Manifold Absolute Pressure (MAP) sensor to read vacuum of the engine, and with this information, we can calculate the load of the engine. Since the camshaft dictates so much of the running characteristics of an engine, camshaft consideration when choosing EFI is equally important.

The compact, bolt-on unit has very few wires, an internal regulator, and on-board ECU hidden behind the front plate. Many of the necessary sensors are mated directly to the throttle body to keep installation issues low.

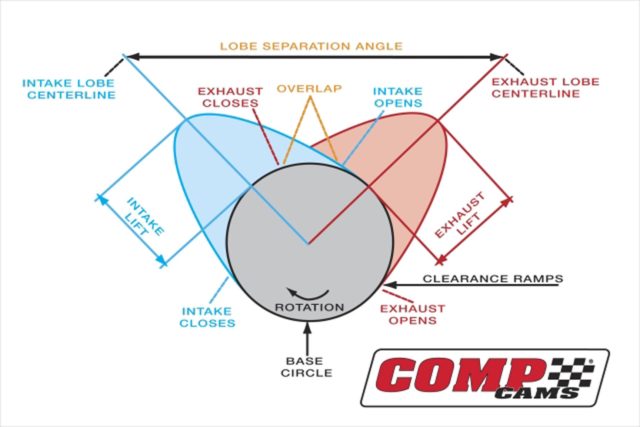

Using a larger duration camshaft will typically cause more valve overlap, thereby lowering engine vacuum. Conversely, a camshaft with a larger lobe centerline spread will typically allow for more engine vacuum due to less valve overlap. When selecting a camshaft for use with EFI, you want to keep valve overlap to a minimum, so, when using larger duration camshafts, you will also want a larger centerline to limit the time both intake and exhaust valves are open.

Ignition timing is even more important with EFI due to the precision that EFI offers for fuel control. – Ken Farrell, FiTech

FiTech EFI systems attempt to be as accommodating as possible for low-vacuum engines. We do have engines running with as little as five-inches of vacuum at idle, although some additional adjusting of the software is necessary. That is one of the benefits of using a computer to tune the fuel mixture throughout the entire operating range of the engine. FiTech systems are designed to be self-tuning, thanks to a few inputs from various sensors. The MAP sensor tells the computer how much load is put on the engine at every RPM, including idle, to help the computer input the correct amount of fuel. A nice, clean vacuum signal helps transmit the necessary information, so the more vacuum the engine makes at idle will help the system self-tune easier.

This diagram from Comp Cams helps illustrate how cam lobe duration and position of the center line can affect overlap. Larger duration cams and closer center lines can increase the amount of overlap, thereby decreasing engine vacuum.

What part does an engine's stroke play when delivering fuel with EFI?

The stroke of the engine only affects the cubic-inch displacement of the engine and has no direct effect on the EFI.

How does EFI interact with ignition timing?

Ignition timing is even more important with EFI due to the precision that EFI offers for fuel control. With EFI, you are able to use a more aggressive timing curve than you may be able to with a carburetor, because of the ability to control the air/fuel ratio at varying load and RPM.

Set For Timing

Better control of your ignition's timing is another benefit of EFI. FiTech's kits offer timing control, but it is not required. To use the availability of timing control, you will need to install a two-wire distributor like this MSD Pro Billet distributor. With the initial timing set and the distributor locked down, you can the use the EFI's computer to adjust timing for use with nitrous, boost, or simply to get better precision on your engine's firing. FiTech's website has more info on compatibility and availability.

One feature we offer is timing control. When using this function on one of our EFI systems, it allows for a greater range of tuning that would otherwise be less efficient with a standard, ready-to-run ignition on higher horsepower applications. The reason for this increase in efficiency is the same as the air/fuel ratio adjustability, the ability to more precisely control timing at different loads and RPM.

Does EFI typically use the same initial timing, or can it be modified for more performance/economy?

EFI typically allows for more aggressive timing for both performance and economy depending on the engines needs and what it is capable of handling. An example would be if the vehicle is turbo/supercharged, or using nitrous. In these instances, you would want to use timing control to retard timing under boost or nitrous activation to allow the engine to perform safely. A side note though, unlike the air/fuel ratio that optimizes for peak efficiency, the timing control function is NOT self-learning, and you must set the curve yourself for peak efficiency and safety for your engine.

What engine specifics are crucial for proper fuel management?

The EFI is directly affected by multiple engine parameters, such as camshaft duration/lift/lobe separation, engine size, engine vacuum (dictated by the cam), and fuel type. These all directly affect the EFI and fuel management calculations greatly. These are all used to calculate the VE (volumetric efficiency) of the engine, and thus, how much fuel the EFI needs to deliver to run the engine properly.

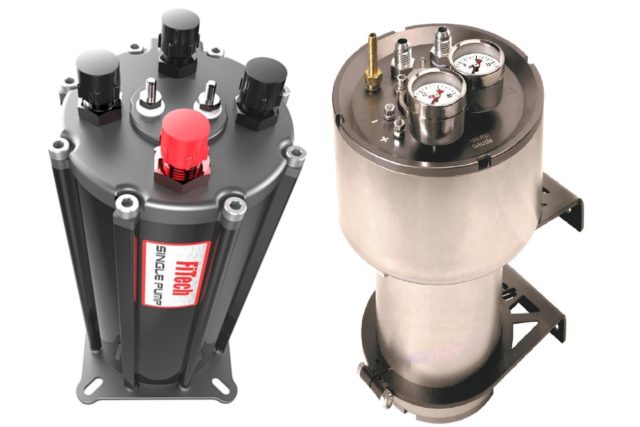

FiTech has various fuel pump assemblies to provide the proper pressure to your EFI, but they also have sump units, which are designed to work with a factory mechanical pump. They each have an electric fuel pump that supplies the high pressure for the EFI, but also utilize a float mechanism that keeps them supplied with the proper amount of fuel from the stock (low pressure) mechanical pump. The G-Sump (left) is designed for high-G applications and the Fuel Command Center (right) is for more typical applications.

What does the computer NEED to know?

The more information an EFI system can collect, the better it can predict precisely what the engine needs. At minimum, our throttle body systems read vacuum (MAP), Air Fuel Ratio (O2), Throttle Position (TPS), Intake Air Temperature (IAT), and Coolant Temperature (CTS).

The benefit of EFI is being able to control fuel through a broad range of operating parameters. FiTech offers these oxygen sensor bungs that allow the use of wide-band O2 sensors but don't require welding. From there, the self-learning ECU keeps the air/fuel in trim. End users can tweak the tune through this hand-held controller in the Pro-Tuning option.

What components MUST be considered when going with EFI?

EFI requires constant and stable fuel pressure to operate consistently. Though there are many ways to deliver fuel to a fuel injection system, some are better than others in certain applications. If an electric EFI pump ever sucks air, it will drop fuel pressure immediately causing drivability issues.

Though there are many ways to deliver fuel to a fuel injection system, some are better than others in certain applications. – Ken Farrell, FiTech

One of the most overlooked items of a vehicle when switching to fuel injection is the existing electrical system of the vehicle. More electronics on a vehicle requires the improvement of power distribution, grounds, and larger amperage alternators.

With that in mind, what is electronic noise and how can it affect EFI?

Electronic noise is electronic interference caused by exterior electrical sources such as the ignition system, alternator, fuel pump, etc. These varying voltage circuits produce an interference in the signals the EFI is receiving from its sensors, which can cause the EFI to run poorly or otherwise have performance issues due to the improper readings.

How can enthusiasts eliminate or limit the effects of electronic noise?

To eliminate electronic noise, you must make sure that all power, ground, and signal connections for the EFI and vehicle electrical systems are well connected. Also, you must isolate any high voltage circuits such as ignition wires or alternator wiring away from sensor circuits of the EFI, such as the tach-signal wire. This will help prevent possible issues in the future for the EFI system, and help ensure your EFI operates as it should for years to come.

Bolt-on EFI is no longer a cookie-cutter option. FiTech has systems designed for dual-four and boosted applications. They just recently unveiled their two-barrel prototype at this year's SEMA show in Vegas!

Today's EFI systems are no longer the overly-sophisticated systems only understood by those with thick-rimmed glasses and pocket protectors. Fuel injection is more suited to the garage-based enthusiast than it has ever been, and thanks to trickle-down technology, the cost has come down significantly. Bolt-on EFI systems now rival the price-points of many old-school carburetors, while the benefits significantly outweigh them. Check them out for yourself and see!

Source: https://www.chevyhardcore.com/tech-stories/efi-questions-answered-with-the-help-of-ken-farrell-at-fitech/

0 Response to "My Fitech Easy Street Has No Rpm Reading"

Post a Comment